Finally!! Just want to let you all know, nothing can be done if you dont try it!! Hurray! After wasting 4 days I knew that what is the problem! Power source, Yes. You should use a power source with 5A rating or it might not run properly.

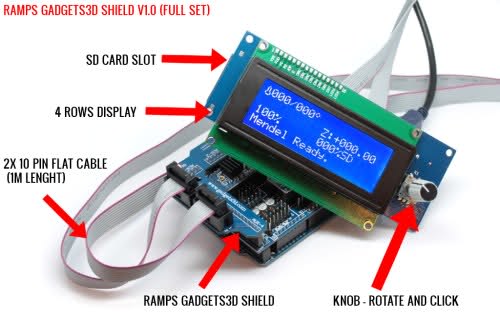

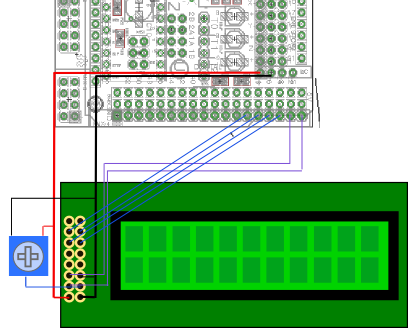

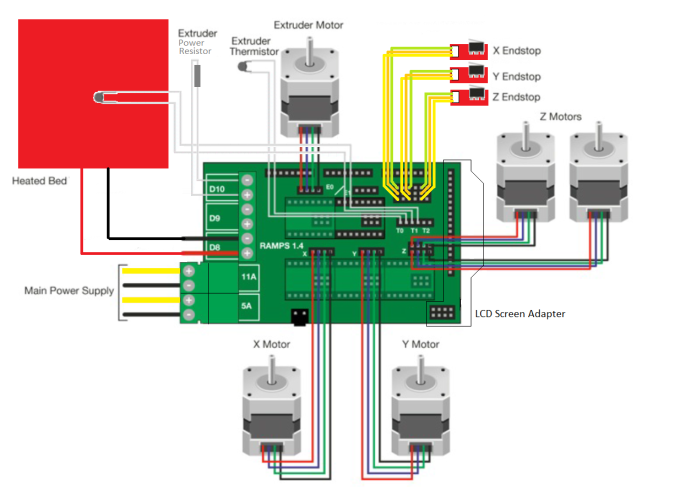

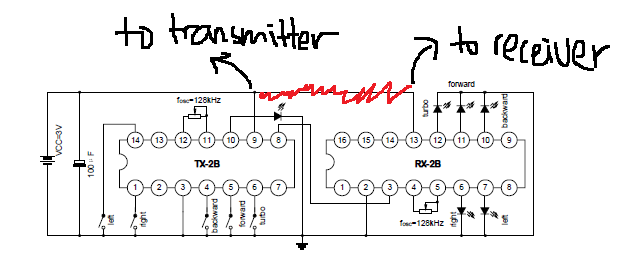

Start with the wiring parts, what you need to do is just refer to this figure:

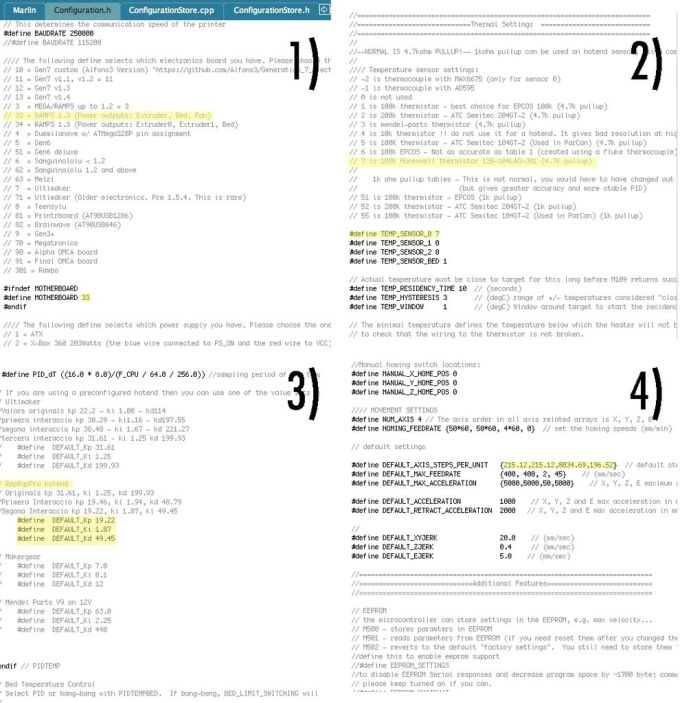

THEN, let's start the firmware setup/modification one by one. first of all, kindly download Marlin firmware from Github(https://github.com/MarlinFirmware/Marlin). After downloaded the file, extract it and open the Marlin folder. Try to find Marlin.ino which required Arduino (http://arduino.cc/en/Main/Software) to open it.

Configuring and compilation

What you need to know before starting:

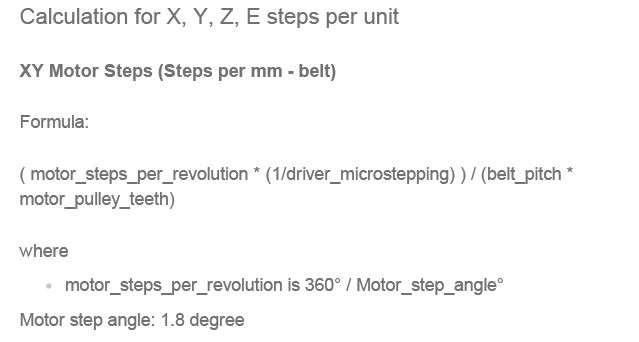

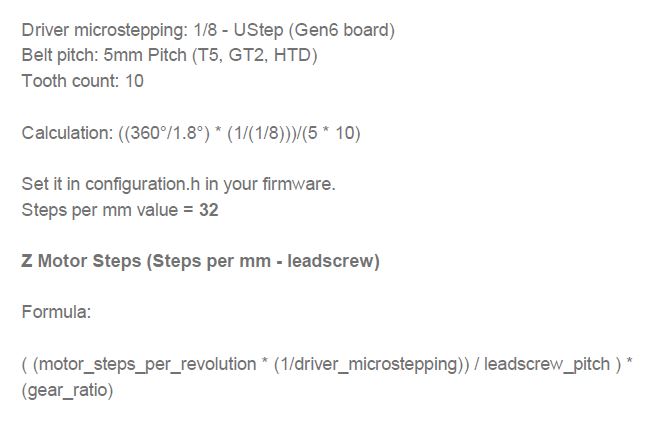

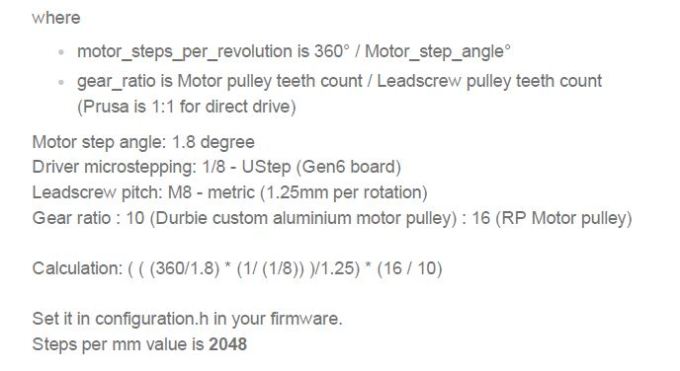

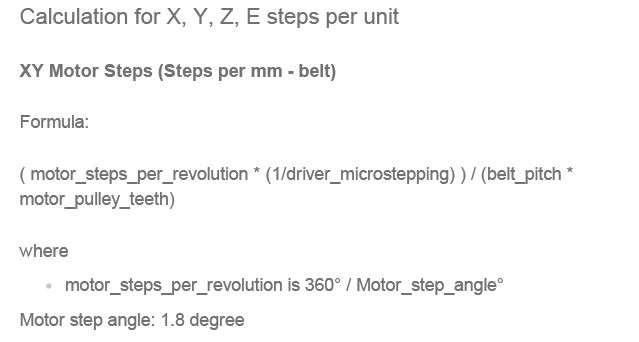

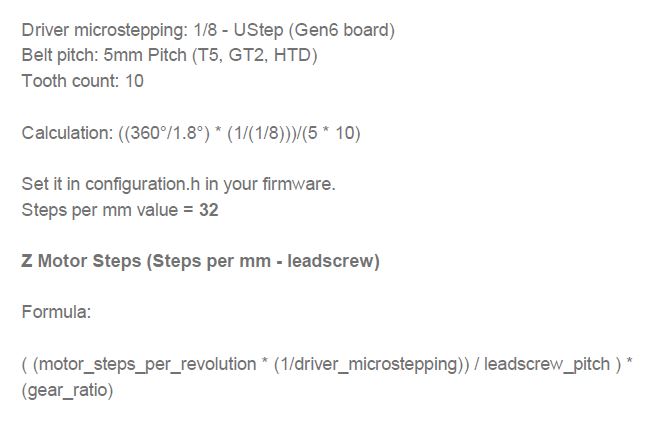

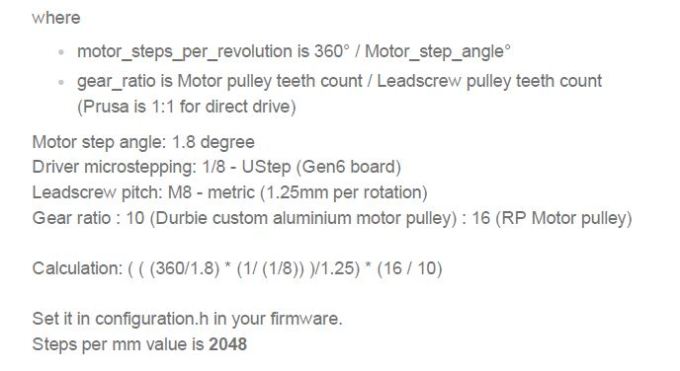

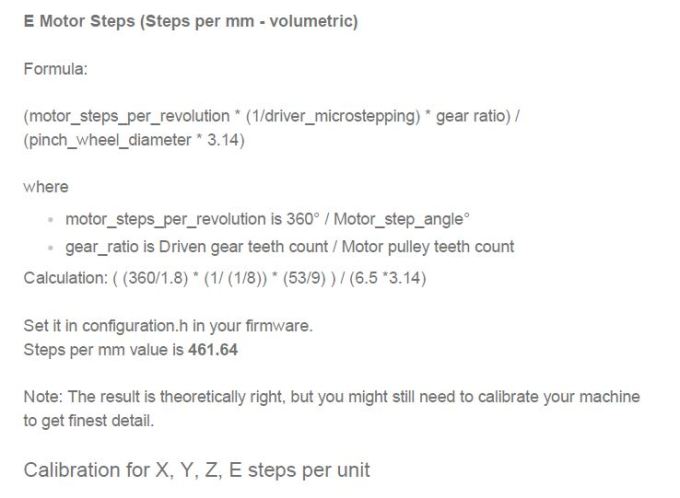

- What kind of printer you are using. If you are using a Cartesian printer (like the Prusa i3), you are going to need to calculate the steps/mm for each axis and for the extruder. To figure this out, you can go to http://prusaprinters.org/calculator/ or Triffid_Hunter's_Calibration_Guide. Write down the values you get for everything.

- You need to know what kind of drive is being used with your printer. If it's a belt, you need to know what kind. If it's a screw, need to know what kind.

- The Prusa i3 uses belts for X and Y, and screws for Z.

- A host software like Printrun or Repetier or even Octoprint.

- Install the arduino software IDE/toolset, version 1.0.5 or 1.0.6 from http://www.arduino.cc/en/Main/Software

- Download the Marlin firmware from https://github.com/MarlinFirmware/Marlin (see the Download Zip button), or use git to clone it (if you know how to use git).

- Extract the firmware to a directory of your choice.

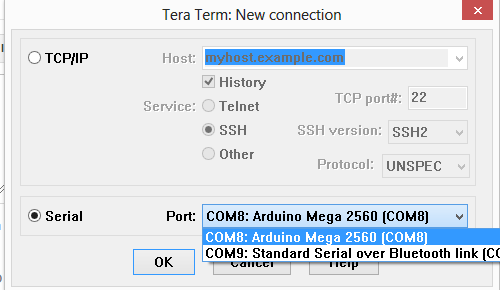

- Start the arduino IDE. Select Tools -> Board -> Arduino Mega 2560 (or whatever your microcontroller is)

- Select the correct serial port in Tools ->Serial Port, usually there is only one option.

- Open Marlin.ino in /path/to/Marlin/Marlin

- Browse to boards.h

- This is a list of motherboard types. You'll need to figure out which one you need and write down the word after #define on that line.

- Example: If you're using a RAMPS 1.4 with a extruder, fan (optional) and heated bed, then you'd need RAMPS_13_EFB.

- Browse to Configuration.h

- Write down the value given in #define BAUDRATE for later.

- At the line that says #define MOTHERBOARD, replace whatever follows MOTHERBOARD with what you chose earlier.

- Set the #define EXTRUDERS to the number of extruders that you have.

- For the TEMP_SENSOR lines, you have to know what kind of thermistor is used by your hot end and heated bed (if you have one). Set the values for these to ones that match the list directly above the lines.

- If you have an extruder on E0 and a heated bed, you just need to set TEMP_SENSOR_0 and TEMP_SENSOR_BED.

- Scroll down to MAX_HEATER_TEMP. If you know that your hotend shouldn't go above a certain value (the Budaschnozzle should not exceed 240C-242C), then change it here. Same for MAX_BED_TEMP.

- Leave the PIDTEMP stuff alone for now, we'll get back to it later.

- Further down the page, look for the Mechanical Settings area.

- For the INVERT_X_DIR and related lines, set it for Mendel if you are using a Mendel-type printer. Otherwise, consult the documentation for your printer design.

- For X_HOME_DIR and the similar commands for Y and Z, look where your endstops are. If a endstop is configured to be at the 0 position for that axis, the setting here needs to be -1. Otherwise, it needs to be 1.

- The X_MIN_POS, X_MAX_POS, and related entries should correspond to the printable area on your bed. The defaults are common, but if you have a bigger/smaller print area, you will need to change this.

- Please note that 0,0 should be the cartesian "bottom left" of your print-bed, if your axis homes beyond the bed in any direction, you can use a *negative value* for the X_MIN_POS and Y_MIN_POS to compensate. (If your prints never wind up in the center of the bed, this is the culprit). Also See Configuring Marlin Bed Dimensions.

- Ignore the auto bed leveling area for now. Hopefully you will never need it.

- Time for the Feed rates and Steps/mm! You're almost done.

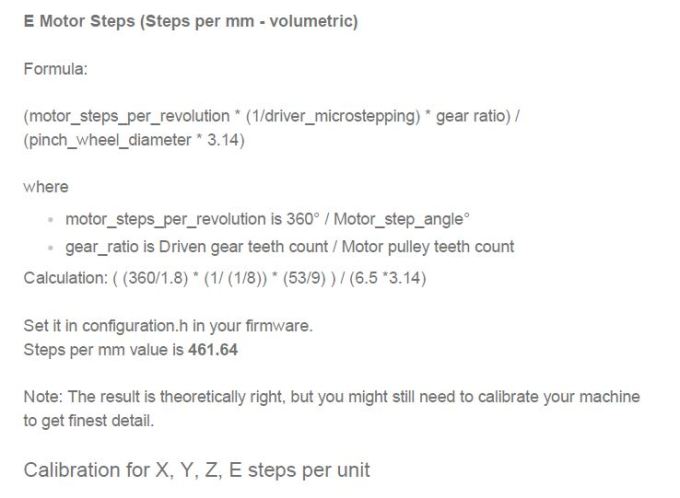

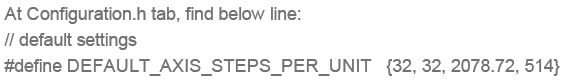

- For #define DEFAULT_AXIS_STEPS_PER_UNIT, you will need to use the values you calculated for your different printer axes and extruder (see above). The order is {X, Y, Z, E}

- For DEFAULT_MAX_FEEDRATE, this is the fastest (in mm/s) the printer is allowed to go.

- For a Prusa i3, setting the Z axis value to 2 is a good idea.

- DEFAULT_MAX_ACCELERATION is something else that should be tuned based on how good you built the hardware of your printer.

- You should probably turn DEFAULT_ACCELERATION to a lower value initially (like 200) and adjust the acceleration later once you get everything calibrated and tuned.

- If you have an LCD or button panel for your printer, uncomment the respective lines for it. Otherwise, save because you are done!

- Click the Upload button.

- If all goes well, the firmware has uploaded.

Finally, just insert/replace the value you had calculated into here:

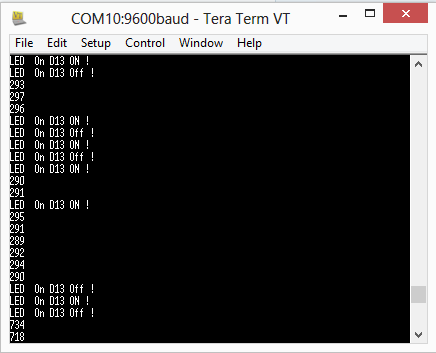

DONE!! Upload your programming to Arduino and test it now!

Power up Arduino and connect it with Repetier host. The rest I just leave it to you, GOOD LUCK!

Repetier Host: http://www.repetier.com/download-software/

After X and Y axis were fixed, I try to draw something using Repetier Host software to confirm the axis were well calibrated.

Then did the Z axis! Since every parts was DIY, it seems.... Hrm, as long as it can use, no problem right?! Going to make it bigger like 25x25x25 cm^3 after I gather the Canon M-series printer parts.

Remember to tidy up the cables and give them a tag!!

Buy a power supply up to 12V 5 A or I think it could hardly work for you! Trust me!

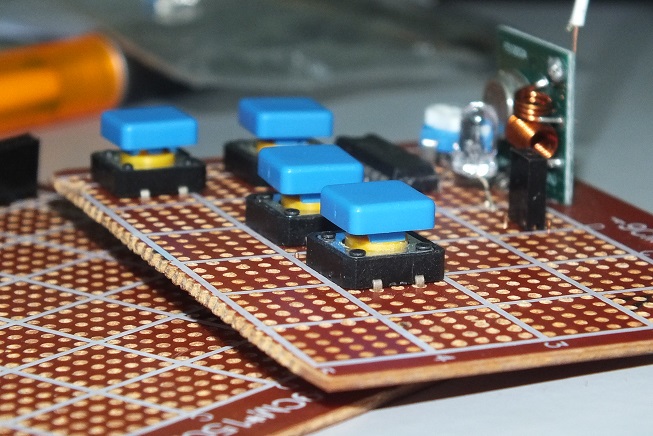

Finally make a small "house" for the power supply and those microcontroller. It need the fan for long term use, dont forget!

If you interested in doing this cheap 3D printer can pm me!! (https://www.facebook.com/Arduino-wholesale-Msia-only-1701856016767472/?ref=aymt_homepage_panel)